Over the operation time, water wells gradually lose their discharge rate due to many reasons including: mineral incrustation, migration of fine-grained soil into the well and microorganisms’ activities. The severity of this process depends on the well and aquifer conditions, but the followings can be a sign of such problems:

- Reduction in discharge rate over time

- Increase in pump power consumption

- Observation of sand in pumped water and water quality degradation

- Lower dynamic level

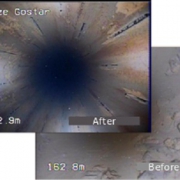

Accurate identification of the problem and well condition is obtained by video inspection, then chemical or physical methods, or combinations of both, according to experts, are used to rehabilitate the well, resulting in:

- Increase in discharge rate

- Decrease in power costs

- Elimination of sand in pumped water and water quality enhancement

- More durability of electromotor and pump

- Well development and incrustations removal radially, even beyond gravel pack

- Elimination of stress on casing and reducing the risk of casing destruction

Incrustations removal by chemical methods

In wells with hard incrustations where incrustations removal is not applicable by common physical methods, chemicals are used. These materials dissolve sediments on casing, gravel and aquifer and loosens incrustations. Then, the dissolved and loosened sediments are removed from the well by brushing, surging or pumping.

Incrustations removal by compressed air impact (Airshock)

The most modern water rehabilitation technology used all around the world is Airshock method. This system causes the burst of compressed air inside the well in a fraction of a second. The compressed air at the pressure of 20 to 200 bar outbursts in less than 5 milliseconds, creating a powerful wave that crushes the hard incrustations and disjoints them from the casing. This operation cleanses the screens and gravel pack resulting in discharge rate increase.