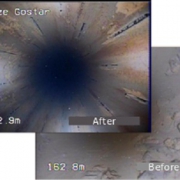

Airlift method is used to remove water and submerged solid particles from the water well. The advantages of this method make it a perfect replacement for common drilling and dredging methods employed for operating wells. By such a method, compressed air is infused to the airlift pump located deep down the well. The air is then released inside the well making a mixture of water and air with a density less than the surrounding water, causing a lift of the mixture. The result is a three-phase flow through the embedded pipe to the outside of the well carrying the removed debris, sand and gravel.

We are able to clear the wells of deposits with liquid Nitrogen and Airlift pump up to the depth of 350 m. In comparison to drilling, this method is:

-

- capable of removing coarse size solids of sand, gravel and rubbles

- more reliable

- faster in removing debris

- capable of removing debris even in wells with deformed or ruptured casings

- not damaging casings of old wells.